Why Pulmonary Monitoring Devices Rely on KNF Pumps

KNF’s compact, reliable gas diaphragm pumps are essential components of critical pulmonary monitoring devices.

Monitoring a patient’s pulmonary function is a critical part of many medical applications. Pulmonary monitoring devices extract small amounts of the patient’s breath and transfer them to gas sensors via a pump. These analyzers then measure the concentration of CO2, O2, and other gases to ensure safety during medical procedures – especially during anesthesia or sedation. Diaphragm pumps are an essential component of medical devices that perform this analysis.

Pulmonary Monitoring Ensures Patient Safety

Monitoring gases in medical applications is an important process, which requires highly specialized equipment. The process involves drawing in a patient’s exhaled breath and passing it through an analyzer, which measures the concentration of important gases like O2 and CO2 (capnography). Many systems also measure anesthetic agents like N2O, enflurane, desflurane, and sevoflurane to ensure patients are receiving the proper doses of these agents. This helps medical professionals confirm that the endotracheal tube is placed properly during sedation. It also allows them to assess the patient’s airway integrity and ensure they are breathing properly.

Monitoring a patient’s pulmonary function allows medical professionals to predict complications that other types of monitoring cannot. Detecting a change in CO2 levels can help prevent embolisms and indicate blood flow and tissue abnormalities. Pulmonary monitoring is also important outside of surgical applications. CO2 levels can help doctors predict outcomes for patients in intensive care settings. Smaller, mobile pulmonary monitoring devices can also be used to measure the effectiveness of chest compressions during CPR.

Reliability is Essential When Lives Are at Stake

Because many of these devices are operating in life-critical environments, pulmonary monitoring equipment requires pumps that are consistent and reliable. These applications demand continuous operation, as failure could result in severe consequences for the patient. Because the analyzers are used in surgical environments close to a patient, they need to be highly clean and produce minimal noise and vibration. Low power consumption is also a requirement. Ideally, the pump will be placed close to the sensor to ensure sample integrity and fast results, so compactness and customizability are also essential.

KNF NMP Series Pumps Meet the Strict Need of Pulmonary Monitoring Systems

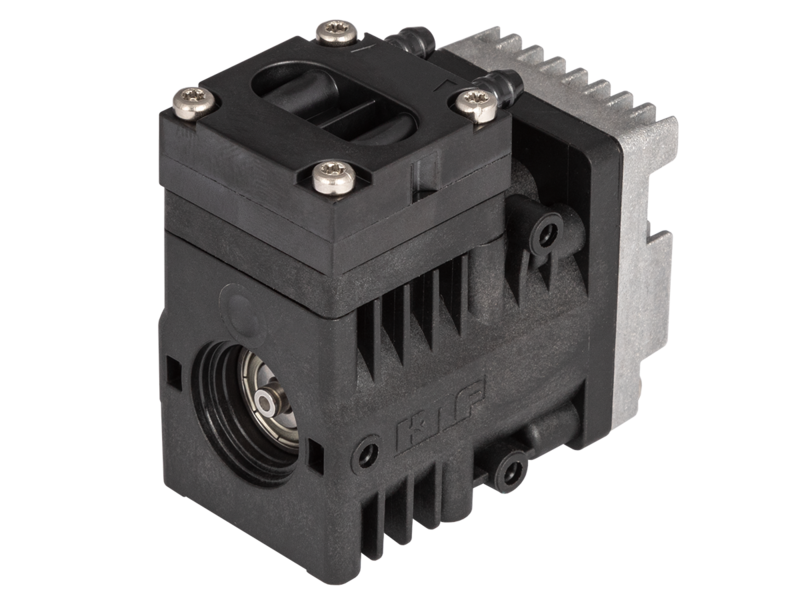

KNF’s NMP 015.1.2 offers the reliability demanded of pulmonary monitoring applications along with a compact design. It features a maximum flow rate of 2.2 l/min with maximum pressure of 0.55 bar (rel.) and maximum vacuum of 600 mbar (rel.). It is available with a variety of customization options, including a digitally adjustable motor. The NMP 015.1.2 runs maintenance free and is capable of operating at a very low noise level.

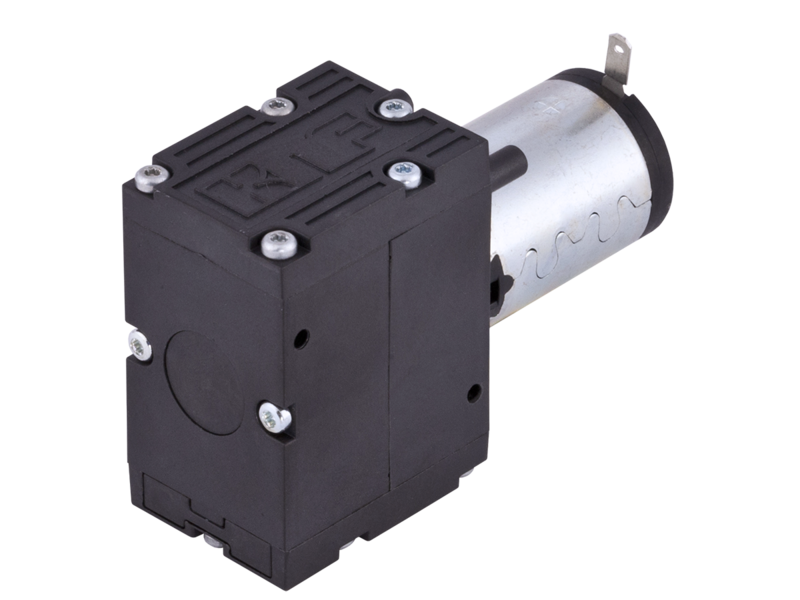

For pulmonary monitoring requiring higher flow, the NMP 830 should be considered. It offers a maximum flow rate of 3.1 l/min, maximum pressure of 1.4 bar (rel.) and maximum vacuum of 250 mbar (abs.). The NMP 830 provides an excellent performance-to-size ratio, along with low pulsation and quiet operation required of pulmonary monitoring applications.