KNF diaphragm gas pumps transfer or compress gases and vapors and generate vacuum without contaminating t...

Pump Motor Parameterization Provides Outstanding Control Capabilities

Revolutionary motor technology allows KNF pumps to offer high levels of control

Advancements in technology allow KNF to factory build products with state-of-the-art pump motor parameterization options for its customers. But what is parameterization? And what kind of advantages can it provide? Modern motor technology allows for a multitude of new possibilities in terms of customizability and unprecedented precision. This can lead to increased productivity, extend pump life and provide critical information to optimize operations.

Pump Motor Parameterization Allows for Advanced Control

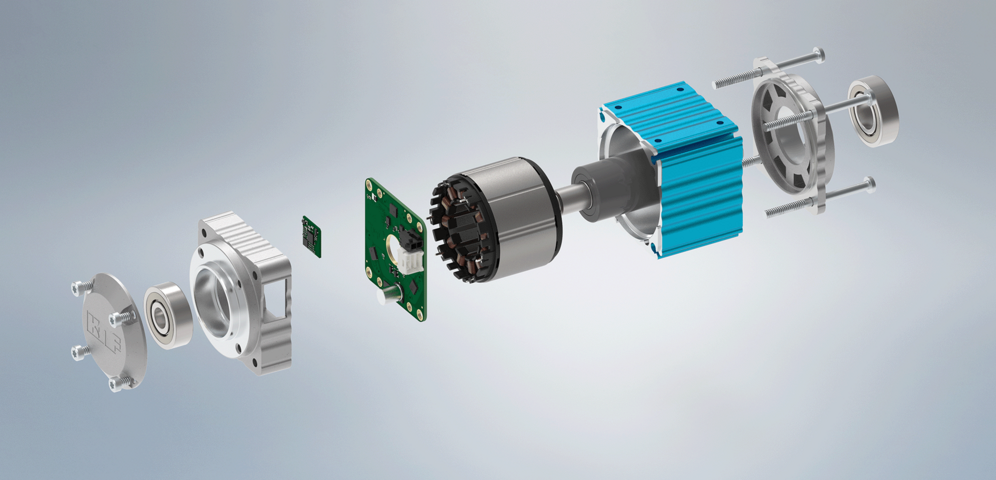

Advanced motor technology has created new opportunities for pump motor parameterization. Brushless Direct Current (BLDC) motors allow for closed-loop communication between the controller and the motor, enabling extensive customization. This allows KNF to tailor pumps to customer specific needs. Aspects like speed, ramp, and startup can be programmed in advance and adjusted to fit application specific needs.

Detailed Motor Status at All Times

Parameterization clearly and consistently provides essential motor information for customers. Depending on the motor type, users can see the motor status in real time, including detailed information like speed, temperature, and electrical current draw. Customers can also receive error messages when the motor is not operating properly. Pump motor parameterization allows for a wide variety of electronic control and communication options. KNF offers a specifically designed control protocol that can be transmitted to pump motors through the Universal Asynchronous Receiver Transmitter (UART). Customers can also control motor RPMs via pulse-width modulation (PWM) signal or via an analog signal. All of these customization options provide customers with advantages like improved performance, reduced operating costs, and longer pump service life.

Parameterizable Speed Provides Accurate and Efficient Flow

Many gas and liquid applications rely on pumps that provide consistent and accurate media flow. This can be achieved via pump motor parameterization, where motor speeds can be digitally set and adjusted to provide the exact flow needed. KNF pumps allow for maximum and minimum speed ranges to be set, making them ideal for applications that require changes in flow rates. Motor speed can also be set to a fixed value, making them equally strong for applications where consistent flow is required. Some pumps allow customers to set up detailed and complex operating profiles, allowing for further control over motor speed. The ability to program and adjust motor speed provides users with an additional level of control over their operations, reduce energy consumption and extend pump service life. Both liquid applications, like inkjet printing and dosing, and gas applications, like medical diagnostics and spectroscopy, benefit greatly from these customizable features.

Speed Ramp Settings Reduce Unnecessary Energy Consumption Peaks

Motor speed ramp settings allow maximum acceleration to be defined, keeping motor speed in line with the actual demand of the application. This reduces high electric loads caused by drastic speed changes, reduces wear and increases service life. This is especially beneficial in applications involving analytical instruments. The ability to customize ramp settings allow pressure fluctuations to be equalized quickly without the need for pressure valves or similar components.

Adjustable Starting and Stopping Options Improve Performance

Pump motor parameterization also allows for custom starting and stopping settings. Motors can be set to start and stop either automatically or only after a command has been received. This level of control, coupled with adjustable ramp speed for easy starting and stopping, allow customers to easily adapt the pump to their system. It also helps reduce wear and tear, lowering maintenance costs while increasing reliability and pump life.

Other values like maximum temperature and maximum locked-rotor time can also be set, allowing the motor to stop and issue an error when these thresholds are met. This level of flexibility allows users to adapt pumps to different operating conditions without having to change hardware. Readily accessible, detailed pump information allows customers to make detailed performance adjustments for further optimization.

Parameterizable Motors Available on a Variety of KNF Gas and Liquid Pumps

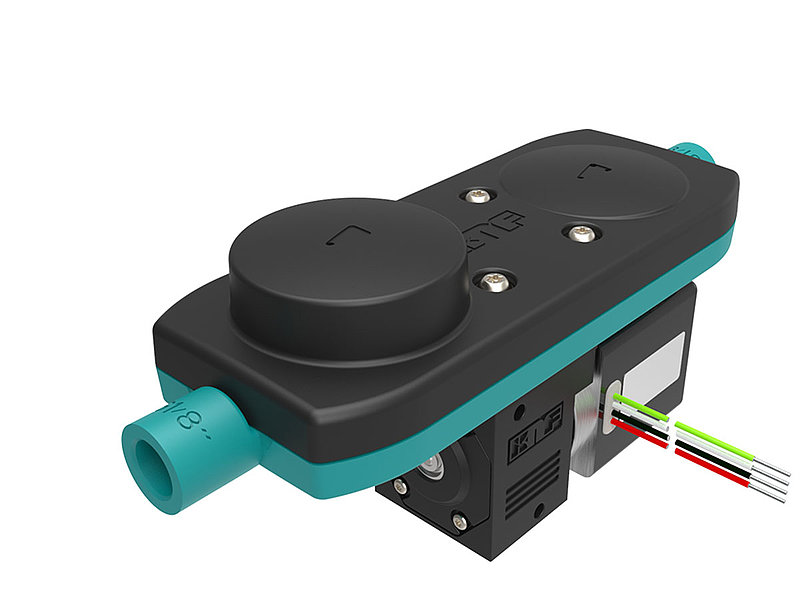

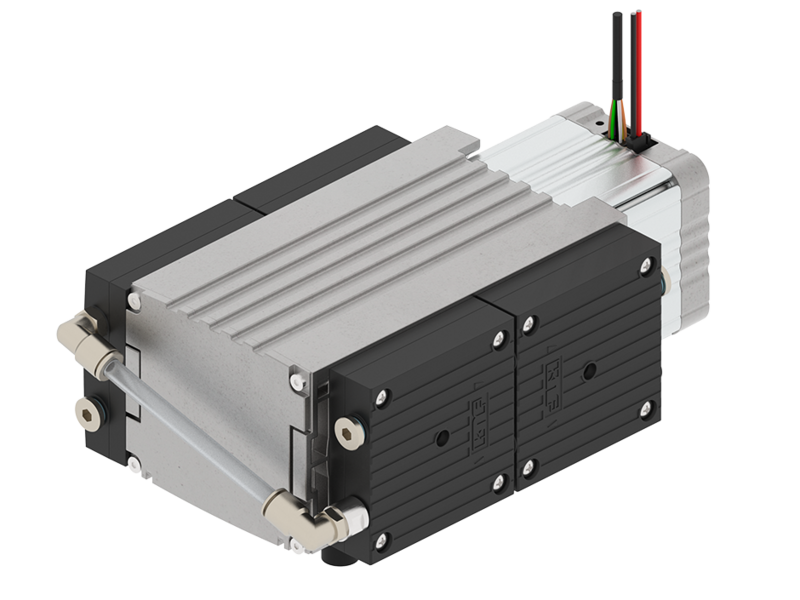

KNF’s offers a wide range of diaphragm pumps that are available with parameterizable motors. Gas pumps like the N 952 come with state-of-the-art MI Motors for precise control. The pump offers a maximum flow rate of 36 l/min, maximum pressure of 0.1 bar (rel.), and ultimate vacuum of 1.5 mbar (abs.). The N 952 provides reliable performance and contamination free media transfer and is available with a variety of diaphragm material options. Parameterization options are available for pumps of various sizes. Smaller pumps, like the NMP 830, are available with parameterizable DC-BI motors.

KNF also offers liquid pumps with parameterizable motors. Products like the FP 70 can be custom designed with brushless DC motors for applications where flow control is essential. It provides a maximum flow rate of 0.7 l/min with a maximum pressure of 2 bar (rel.) and a suction height of 2 mH20. The FP 70 is equipped with smooth flow technology and can be custom designed with different valve and diaphragm materials.